Overview

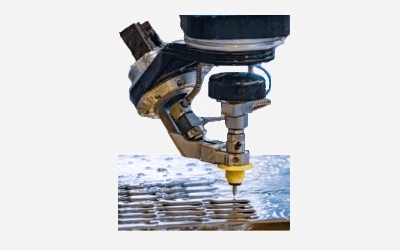

In steel mills, persistent water hammer in high-pressure piping systems often leads to burst pipes, cracked welds and descale header damage. Hunt Valve and RSI worked together to develop a servo controlled proportional poppet descale valve which can be programmed to eliminate water hammer in the system. Hunt Valve brings nearly 100 years of fluid power engineering innovations and solutions to a wide range of industrial and military customers.

Solution

Hardware

RSI assisted with the selection of the servo system including the motor, drive, and roller screw actuator to achieve the required forces to actuate the high pressure valve within the application budget.

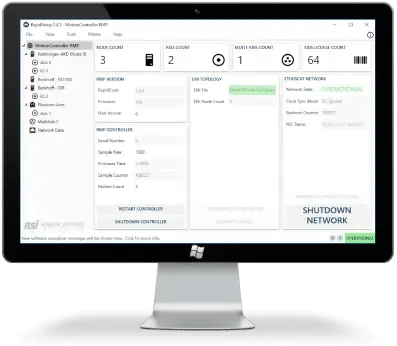

Software

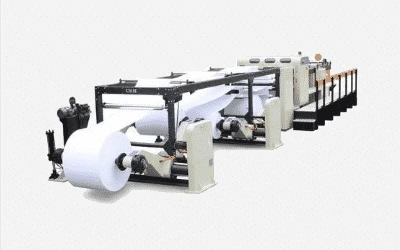

RSI developed an intuitive user interface; enabling maintenance staff to setup a valve profile and quickly test to eliminate water hammer. The application is windows based so it can run on any windows tablet, or laptop making it easier to identify and resolve problems with minimal downtime.

The application we developed logs relevant data to an online server for remote diagnostics and data analytics. The data is analyzed alongside other installed valves to determine if a valve is in need of maintenance.

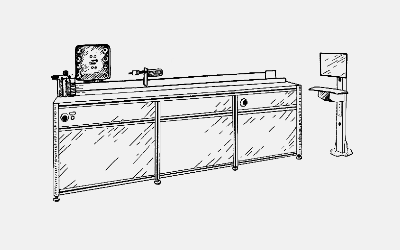

Control Panel

RSI designed and assembled the control panel which houses the servo control system in a dirty, wet, and hot environment. Special precautions were taken to insure the control system could operate in the harsh environment.

Testimonial

“Our experience with RSI has been great on this project. The package developed by RSI, especially the GUI is extremely well done and very user friendly. The field support on a world wide basis has also been excellent and we are very thankful to have RSI as a partner."

- HuntValve

Technologies

Hardware

- Industrial PC: iPC

- Servo Motor

- EtherCAT Servo Drive

- High Force Roller Screw Actuator

Software

- HMI/UI: "RapidValve" custom designed by RSI

- Motion Controller: RMP EtherCAT Motion Controller

- OS: Windows 10

- Framework: .NET 4.5

- Language: C#

Benefits

- Reduced Operating costs.

- 3-5x Extended service life due to less wear and tear on piping systems.

- Intuitive HMI for quick setup and remote monitoring.

Images

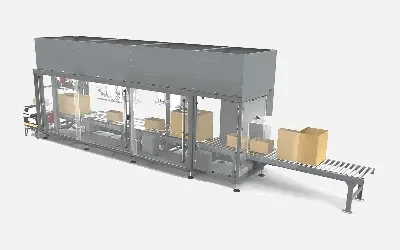

See images of the UI/HMI, Control Panel, and below:

Additional

See documentation on the RapidValve UI here.

.jpg)